KB Global USA

INNOVATIVE LIGHT-GAUGE STEEL BUILDING SOLUTIONS

Manufacturing, Distribution and Construction

Why Choose US

Reason for Choosing KB Global USA

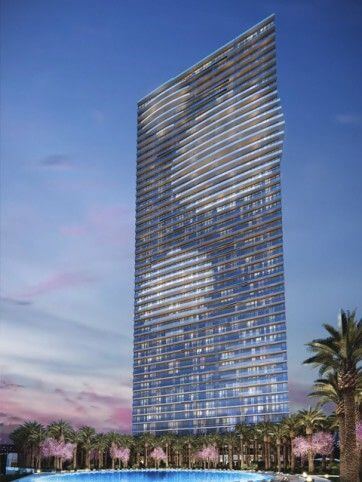

As early adopters of light-gauge steel manufacturing and construction, KB Global USA has a comprehensive understanding of the numerous benefits of building with LGS compared to other building materials. We have been manufacturing and distributing light-gauge steel for almost a decade and have created many relationships both in the supply chain and with local developers, engineers, and contractors. We also offer other miscellaneous building supplies, such as our very own Superboard™, metal strapping, backing, blocking, and a wide range of Simpson Strong-Tie products.

KB Global USA is always striving to add value to our customers while creating a more streamlined and hassle-free experience for our clients, which is why we have incorporated other aspects of the build into our business. We now pride ourselves on being a complete one-stop-shop building solution.

Same day delivery available thoughout South Florida

Light-Gauge Steel

Why light-gauge steel

- LGS framing is stronger, lighter and longer-lasting than wood and CMU block.

- Provides faster, efficient construction with less labor, which means greater ROI for developers.

- Easy to install.

- LGS framing and trusses can be built to withstand any environment – hurricanes (high-winds), fires and earthquakes.

- LGS is non-combustible and non-toxic, which keeps your family safe and saves you money on home insurance.

- Termite and mold proof.

- LGS creates less waste compared to other building materials and the waste that is produced is recycled, making it a sustainable and eco-friendly.

Custom LGS Manufacturing & Framing

Truss Manufacturing & Assembly Line

Custom CFS Manufacturing & Framing

Truss Manufacturing & Assembly Line

-

Architectural Design

Send us your architectural plans.

-

Structural Engineering

Either one of our approved structural engineers or one of your own engineers will design the structural specifications for the building.

-

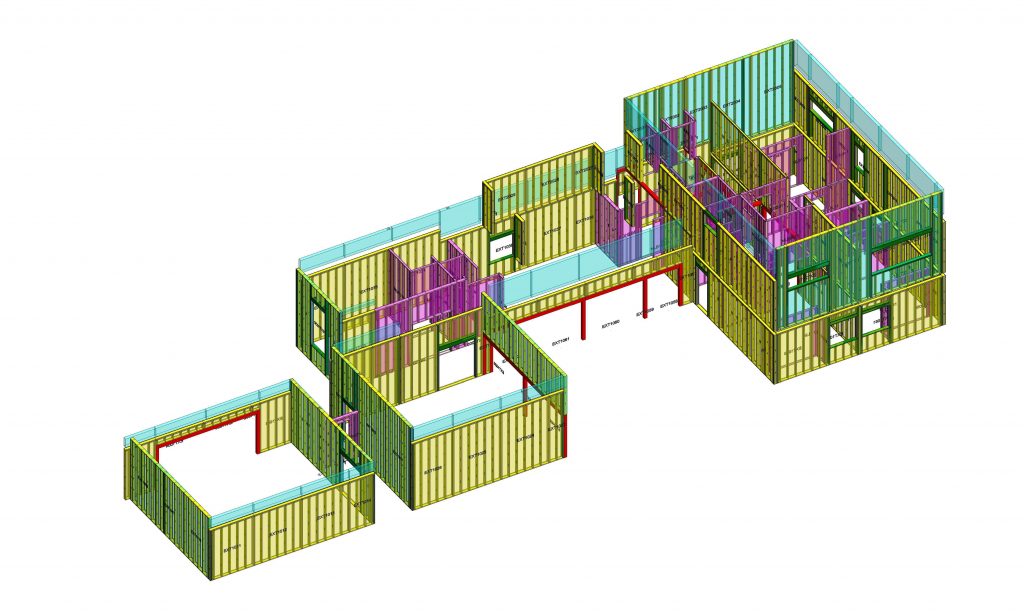

Cross-Check And Design

The architectural and structural models will be input into our MWF software to check everything matches up and the panelizing of the building will begin.

-

Production

Frame members are made with our roll-forming machines and then fabricated into panels on our assembly tables. These panels are then labeled according to their location.

-

Delivery

Panels and Trusses are delivered to the jobsite in order of erection to ensure a smooth installation.

-

Erection

Panels and trusses will be installed according to the numbering in the layout plans.